Crafted, not rushed

Our pacifiers are made with a simple principle: slow production leads to better quality. Instead of choosing fast industrial methods, we rely on a controlled, hand-dipped process that respects the material and its natural properties.

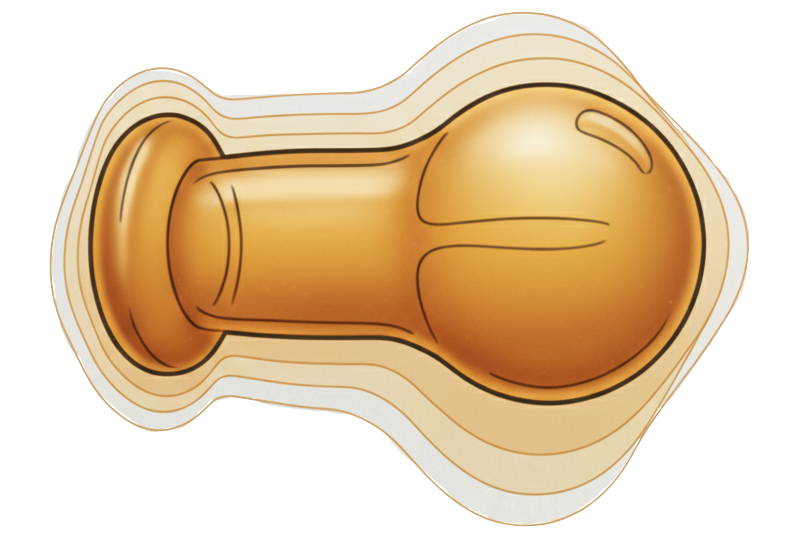

Eight layers, one at a time

Each pacifier is dipped eight times in pure natural latex.

Every dip creates a new layer.

Every layer adds strength.

This gradual build-up gives the pacifier its:

-

firm structure

-

flexibility

-

high tear resistance

-

familiar soft feel for babies

Fast production cannot replicate this level of consistency.

A texture you can feel

The repeated dipping creates a smooth, honey-like surface.

It feels warm, soft and gentle on the skin.

No synthetic coating. No shortcuts. Just pure latex shaped with care.

Why slow matters

A slower method gives us full control over:

-

thickness

-

elasticity

-

durability

-

comfort

The result is a pacifier that reacts naturally to a baby’s sucking rhythm and stays resilient over time.

Naturally derived, naturally treated

Since natural latex is sensitive to temperature, light and airflow, a slow process helps protect its integrity. Each dip is timed and dried under controlled conditions to keep the material stable and safe.

Built for daily use

Eight thin layers create one strong piece.

This structure handles frequent sterilizing, repeated suction and everyday wear without losing its form too quickly.

The philosophy behind it

We choose slow production because it delivers a safer, smoother and more consistent pacifier. It’s a commitment to quality that you can see and your baby can feel.